Twin screw extruder granulation Pelletizing system PP PE Conveyor belt machine

Pelletizing craft : High speed mixer---Spiral Material Loader----twin screw metering feeder--- Twin screw extruder---Hydraulic Screen Changer---die head strand ---Conveyor belt--- Pelletizer

Specification

| Model |

GS-50 |

GS-65 |

GS-75 |

GS-95 |

| Main motor |

35-75 |

45-75 |

75-100 |

132-250 |

| Screw diameter |

50.5 |

62.4 |

71 |

93 |

| L/D |

28-64 |

28-64 |

28-64 |

28-64 |

| Rotate speed |

0-600 |

0-600 |

0-600 |

0-600 |

| Screw material |

bi-metal |

bi-metal |

bi-metal |

bi-metal |

Water demand:

1)Recycling water:water pressure:~0.45MPa

2)Water temperature:≤38℃

3)Industrial soft water(none-ion water )water temperature ≤38℃

4)Circulating water: for barrels cooling; using soft water(distilled water) to prevent scale

5)External circulating water: for cooling internal circulating water and water trough

6)Water supply suggestion: build pool 25~30m3outside of workshop and pump the water

Machine details

1. Name: High speed mixer

Mixing time : 4-6 batches/ hour

Max.output: 400-500kg/h

2. Name: Spiral Material Loader

3 kw

3. Name: twin screw metering feeder

Type:WB-120-LD-2.2,Cycloidal needle wheel deceleration motor

------Power:4 kw;

------Reduction box: speed ratio:11:1,motor and reducer adopt the direct-connected type.

------Inverter:adopting”Dongyuan” AC frequency conversion speed

4. Name: Twin screw extruder

------Gear box

-----Main motor

------Screw

------Barrel

------Heating section

------Soft water cooling system

------Vacuum system

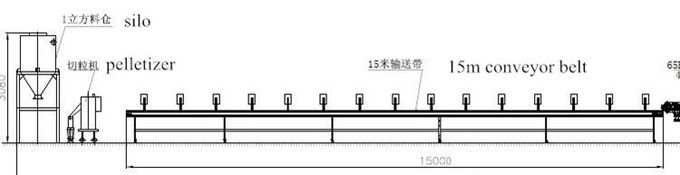

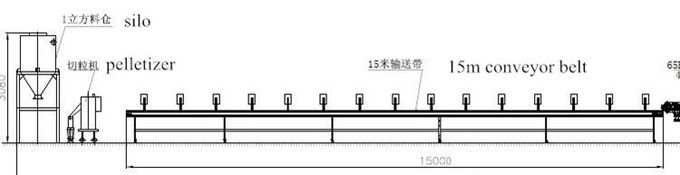

5. Name: Conveyor belt auxiliary system

-------Conveyor Belt:15m,15 PCS drying fan.

-------Pelletizer:one set Power:5.5kw

Contact

Nanjing GS-mach Extrusion Equipment Co.,Ltd

No.12 Shanghu Industrial Park,Jiangning Street, Jiangning District,Nanjing China

Mobile Phone/whatsapp: +86 18851021602

Tel: 86-25-81030382-8:00~17:00

Fax: 86-25-52790852

Email: extruder5@njgsmach.com

Product Picture: