Flame retardant masterbatch of master batch manufacturing machine of PE,ABS,PA,PBT+additives

Master batch machine Introduction:

Parallel co-rotating twin screw extruders have excellent mixing performance,good self cleaning performance and flexible modular configuration characteristics which make

them suitable for processing different types of material systems,and are extensively used in fields of polymer processing ,foodstuff processing and chemical products, especially for various high molecular materials.

In most cases ,parallel co-rotating twin screw extruders are used as mixing equipments .ln processing high molecular materials,the modification process and master batch preparation of polyolefin materials and engineering plastics require sufficient and intensive mixing,which differs depending on material systems, Excellent equipment performance,reasonable mixing process, advanced combination technique and rich processing experience are the key factors determining the success and efficiency of mixing

Application:

1. Mixing Nature-Changing

PE/PP/PS+SBS; PA+EPDM; PP+NBR; EVA+Silicon Rubber, ect.

PE/PA/PC/CPE+ABS(alloy); PBT+PET; PP+PE, ect.

2.Filling Nature-Changing

PE/PP/EVA, ect.+Calcium Carbonate/ Talcum Powder/ Titanic Powder

PP/PA/ABS+Ferous Powders/ Sulphuric Powder/ Ceramic Powder

3.Functional Machine Pellets

PE/PP/PS, etc+Starch; De-composing Machine Pellets

PE/EVA/ABS, etc.+ Carbon Black; Black Machine Pellets

4.Colored Machine Pellets

PE/PP/ABS/AS/PA/EVA/PET+Pigment and Auxiliary

5.Intensified Glass Fibres and Carbon Fibres

PP/PC/ABS/PET ect.+Long Fibres/Carbon Fibres and So On.

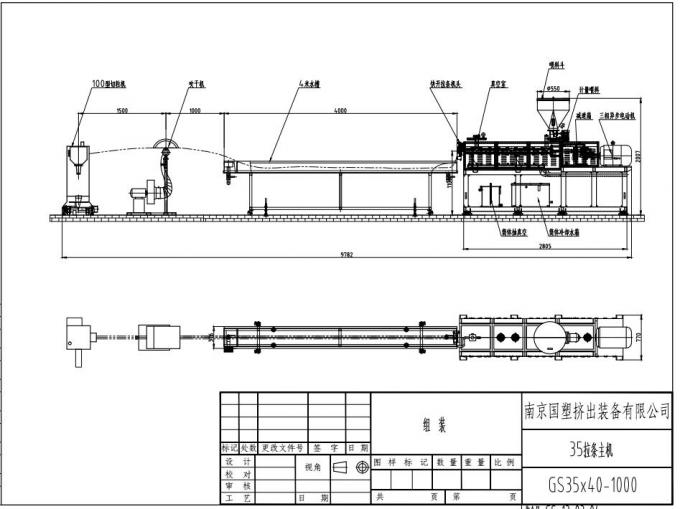

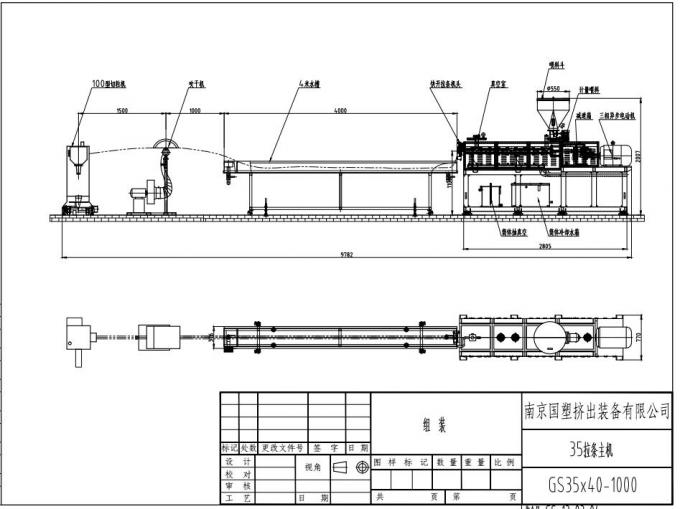

The layout drawing: